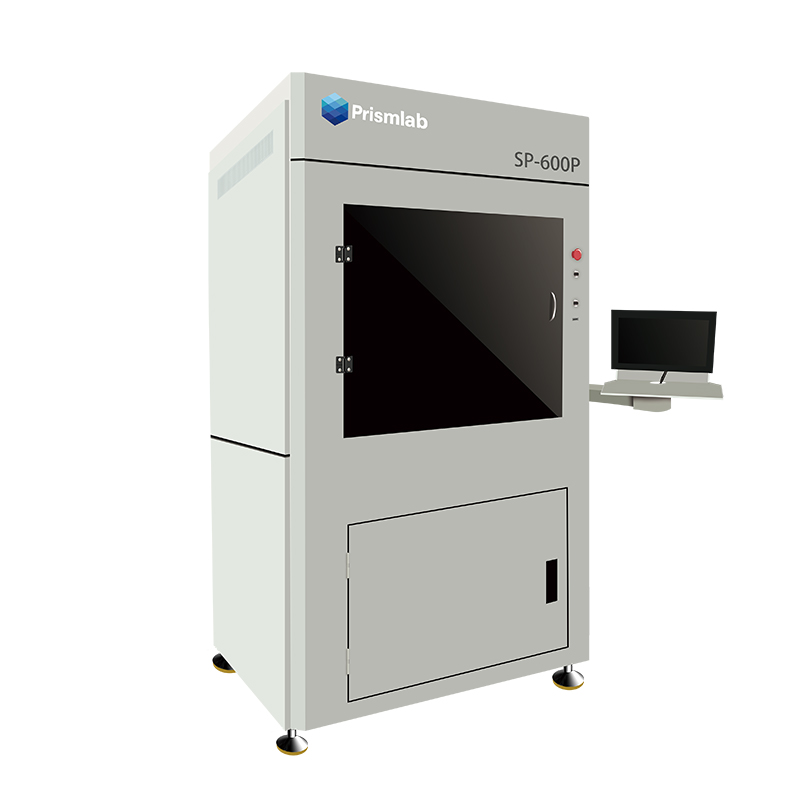

High reputation Prismlab Nano 3d Printer - SP Series SP-600P01X brand high-accuracy SMS 3D Printer – Prismlab

High reputation Prismlab Nano 3d Printer - SP Series SP-600P01X brand high-accuracy SMS 3D Printer – Prismlab Detail:

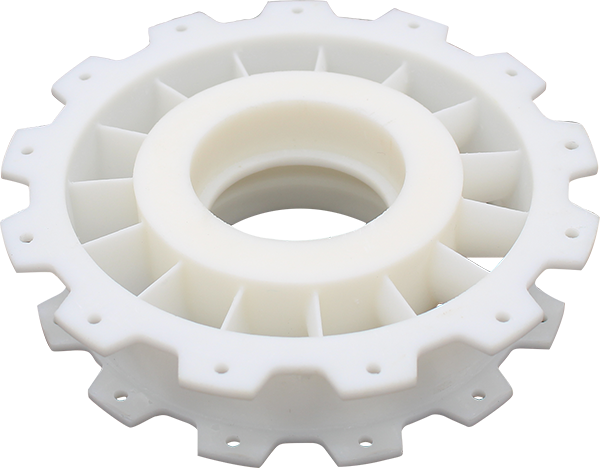

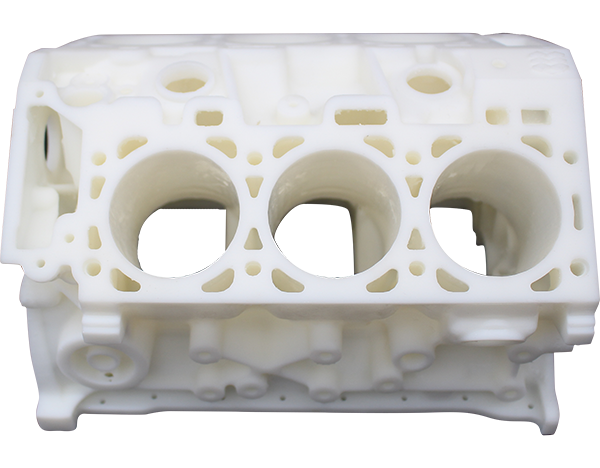

Application of SMS 3D printing technology in mold design and manufacturing:

● Break the shackles of mold as the mother of industry. Through 3D printing, mold free manufacturing can be realized, especially in the aspects of new product research and development, personalized customization, small batch production, complex special-shaped structure products, and non splicing integrated molding and manufacturing. 3D printing can replace the traditional mold manufacturing method and profoundly change the mold industry.

● Direct 3D printing of molds or mold parts that can be used for production. For example, injection molds, stretching molds, die-casting molds, etc. can also be used for mold repair.

Application

Parameters

| Product Name | SP-600P | SP-800P |

| Laser Type | Diode-pumped Solid-state Laser | Diode-pumped Solid-state Laser |

| Wavelength | 355nm | 355nm |

| Laser Power | 3W | 3W |

| Recoating Mode | Intelligent Vacuum Absorptive Scraper | Intelligent Vacuum Absorptive Scraper |

| Normal Build Thickness | 0.1mm | 0.1mm |

| Accuracy | <100mm; ±0.1mm , >100mm;l/1000mmXWorkpiece length | <100mm; ±0.1mm , >100mm;l/1000mmXWorkpiecelength |

| Benchmark Platform | Marble | Marble |

| Precise Build Thickness | 0.05~0.lmm | 0.05-0.1mm |

| Beam Size | 0.1-0.8mm (adjustable) | 0.1-0.8mm (adjustable) |

| Scan Speed | 6-12m/s | 6~12m/s |

| Build Rate | 50-200g/h | 50-200g/h |

| Benchmark Platform | XYZ Integrated Marble Platform | XYZ Integrated Marble Platform |

| Position Repeatability | ±0.01mm | ±0.01mm |

| Main Application | Orthodontics, Aerospace, Art & Design, Architecture, Automobile Accessory, Ed ucation | Orthodontics, Aerospace, Art & Design, Architecture, Automobile Accessory, Education |

| Pre-processing Software | Materialise Magics RP (optional) | Materialise Magics RP (optional) |

| Input File Format | STL | STL |

| Power Requirement | 200-240VAC 50/60HZ, Single phase, lOAmps | 200-240VAC 50/60HZ, Single phase, 10Amps |

| Ambient Temp | 20-26°C | 20-26°C |

| Relative Humidity | Less than 40%, Non-condensing | Less than 40%, Non-condensing |

| Device Dimension | 1.3m X 1.1m X 1.95m | 1.5m X 1.3m X 2.35m |

| Weight | 700kg | 1000kg |

| Max Build Volume | 600mmX600mmX400mm (customizable) | 800mm X 800mm X 400mm (customizable) |

Product detail pictures:

Related Product Guide:

We insist over the principle of development of 'High top quality, Performance, Sincerity and Down-to-earth working approach' to supply you with exceptional services of processing for High reputation Prismlab Nano 3d Printer - SP Series SP-600P01X brand high-accuracy SMS 3D Printer – Prismlab , The product will supply to all over the world, such as: Stuttgart, Nepal, Canberra, By adhering to the principle of "human oriented, winning by quality", our company sincerely welcomes merchants from at home and abroad to visit us, talk business with us and jointly create a brilliant future.

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.