Micro-nano 3D Printer-Core Technology-Key R&D Program of the Ministry of Science and Technology

“Micro-nano Structure Additive Manufacturing Process and Equipment" Project No.: 2018YFB1105400

The core technology of Prismlab MP series precision micro-nano 3D printers - sub-pixel micro-scanning technology is the research result of the national key research and development project "Micro-nano Structure Additive Manufacturing Process and Equipment". This technology can greatly reduce printing errors, print The efficiency is 5-10 times higher than the equipment in the same industry, and it is a real scientific research tool.

The technology is based on the "micro-focusing-micro-scanning" technology of the micro-lens array. Under the same precision conditions, the forming efficiency is more than 30 times higher than that of the DMD chip, which solves the problem of "stuck neck" of the American chip; all parts of the equipment can be made To the independent research and development of domestic anti-aging LCD, in the case of 7*24H non-stop printing, the service life of 10 years can be guaranteed.

Sub-pixel micro-scanning technology-principle

1. Spot reduction (minimum 500nm):

Using the microlens array technology, the light spot projected by the surface is narrowed to obtain a sub-pixel light spot

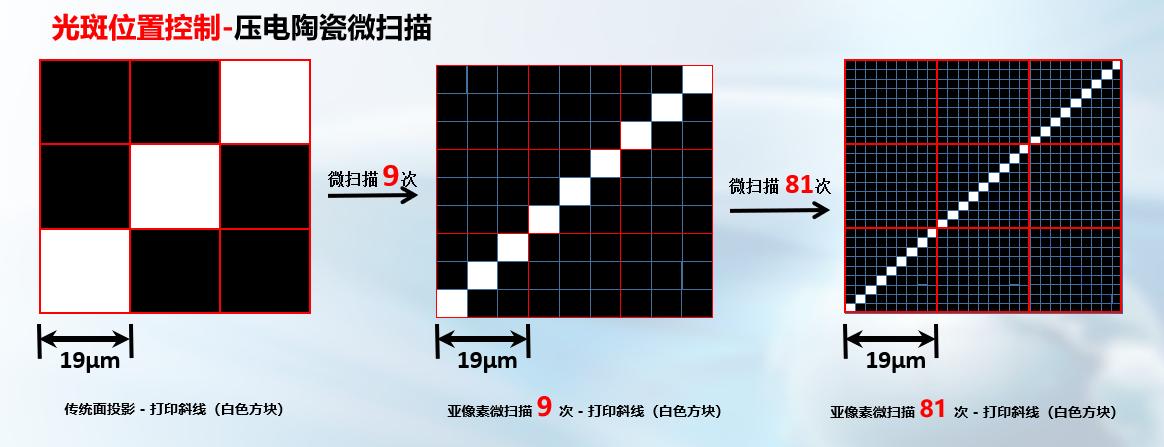

2. Light spot position control:

Using piezoelectric ceramic micro-vibration scanning technology to control sub-pixel light spots for precise physical arrangement

3. Light spot on and off control:

Using sub-pixel electronic control technology to precisely control the lighting/extinguishing of sub-pixel light spots; using piezoelectric ceramics to control sub-pixel light spots for micro-vibration scanning, up to 144 micro-scans

Tips: 1. The micro-displacement accuracy of piezoelectric ceramics can reach 50~100 nanometers, and the displacement time can be ignored;

2. The physical pixel size of the LCD is 19 μm.

Sub-pixel micro-scanning technology does not require splicing, completely avoids splicing errors, and increases printing efficiency by a hundred times

Ø LCD: 1920×1080 pixels; Accuracy requirement: 2μm

Ø The single exposure area of traditional surface projection is 3.84x2.16mm

Ø The single exposure area of sub-pixel micro-scanning is 36.48X20.5mm

Prismlab MP series precision micro-nano 3D printers have domestic self-developed certification and relevant authorization certificates from Europe, the United States and Japan, and their technical strength is more guaranteed.

Post time: Sep-29-2022