CP Series CP-200JD brand SMS industrial ceramic 3D Printer

Working Principle Of 3D Ceramic Printer

In the working process of 3D ceramic printer, it mainly works by using ceramic raw materials. First, it needs to send ceramic raw materials into the interior of 3D printer, fill the raw materials, and then load the pre-designed 3D model, so that the 3D printer can print and design according to the set business model, and realize the function of three-dimensional free forming. In the whole forming process, Can show the difference from the traditional process.

In short, compared with other 3D printers, 3D ceramic printers are more compact, do not need to occupy too much area, and are very suitable for selection. Moreover, 3D ceramic printers on the market have a variety of models and functions to choose from, which can effectively meet the needs of enterprises.

What Are The Advantages Of Ceramic Printing?

Ceramic 3D printing has the following characteristics. Compared with other materials, it is more aesthetic, tactile and outstanding in chemical resistance and biocompatibility, so ceramic 3D printing is often used in medical applications of 3D printing.

Ceramics also have good electrical insulation and high strength. These above determine the unique position of ceramic materials in 3D printing.

The application of ceramics in many industries is of great significance. 3D printed versions of ceramics are rapidly replacing traditional ceramic parts.

When I think of ceramics, I first think of pottery and cooking utensils, but this is only the tip of the iceberg.

Some Industries That Rely On Ceramics

Space Flight

The dimensional stability and low density of ceramics make it an ideal material for rockets and satellites to be sent into space in the form of bearings, seals and heat shields; Parts will undergo extreme temperature changes in space, depending on their relative position to the sun.

Therefore, it is important that materials cannot shrink and expand in these temperature changes. Of course, the cost of sending anything into space is directly related to mass (weight), so lightness is always a priority.

Aviation

The same characteristics are also helpful in the earth's atmosphere. If not, there are more turbulence and (air) friction in the earth's atmosphere to deal with; Ceramics have high wear and heat resistance, so it can be found in various aircraft components, including armor, electrical insulation and fuel nozzles.

Automobile

The hardness and toughness of ceramics are particularly useful in the field of automobile manufacturing. From spark plugs, brakes, sensors and filters, there are countless parts in any given car, including ceramics.

Medical Science

Ceramic is a kind of material with light weight, durability and good biocompatibility. It is an important material in the medical and surgical industry. It can be used in implants, surgical tools and guide rails, as well as diagnostic equipment.

Application

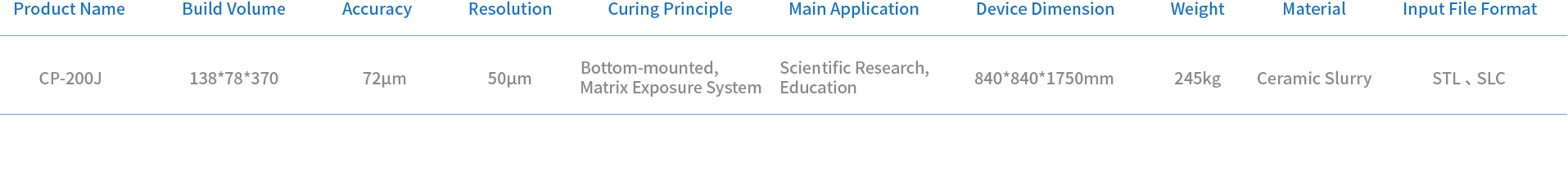

Parameters